Roll Formed Sheaves

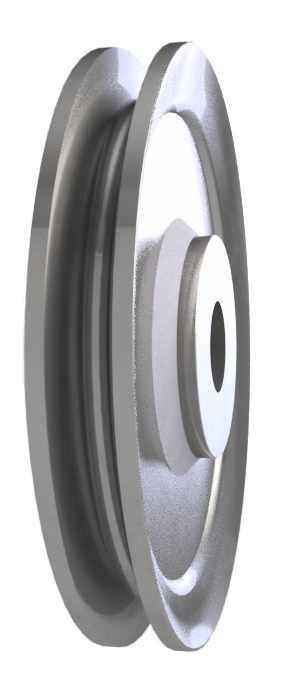

About Roll Formed Sheaves

Roll Formed sheaves are manufactured using a unique process that ensures reliable and economical production for medium-duty applications:

- Pre-Machining: Starts with a steel disc with the outside diameter and inside diameter machined.

- Roll- Forming: Disc is placed into the roll forming machine where it is spun at high speeds while groove dies are pressed into the sides to form the specific rope groove.

- Welding: Pre-machined hubs of a specified outside diameter and length are welded into the formed blanks.

- Post-Machining: Sheave bore machined in lathe for the particular bore option needed.

- Bearing/Bushing Install: If the sheave needs a bearing or bushing, it is installed using a hydraulic press.

Bear Equipment Roll Formed sheaves offer outside diameters from 8″ to 12″, grooves for rope diameters from 1/4″ to 1″, and multiple bore options, catering to a wide range of medium-duty sheave needs.

Specifications

Duty:

Medium Duty

Material:

Steel

Size:

8"-12"

rope size:

1/4"-1"

Bore Options:

- No Bore

- Plain Bore

- Oilite Bushing

- Grooved Bushing

- Needle Bearings

- Ball Bearings

Flame Hardening:

- Not Available

Coating:

- Plain (Standard)

- Paint/Powder-coat/Plating

- (Upon request)

Why Choose Roll Formed Sheaves

High Strength to Weight Design

Unique forming process produces a web profile that reduces unnecessary weight and provides the highest strength to weight ratio.

High Versatility

With a range of outside diameter, rope diameter, and bore options, Roll Formed Sheaves are a versatile solution for any medium duty application

Quick Turnaround

Modular manufacturing process utilizing blank and hub, allow roll formed sheave to be quickly customized to your needs.

Economical & Reliable

Roll forming is an efficient and repeatable process that produces a quality economical sheave.

Roll Formed Sheave Quote Form

Find Your Sheave:

Choose your dimensions and hit next to get started on your roll formed sheave quote.

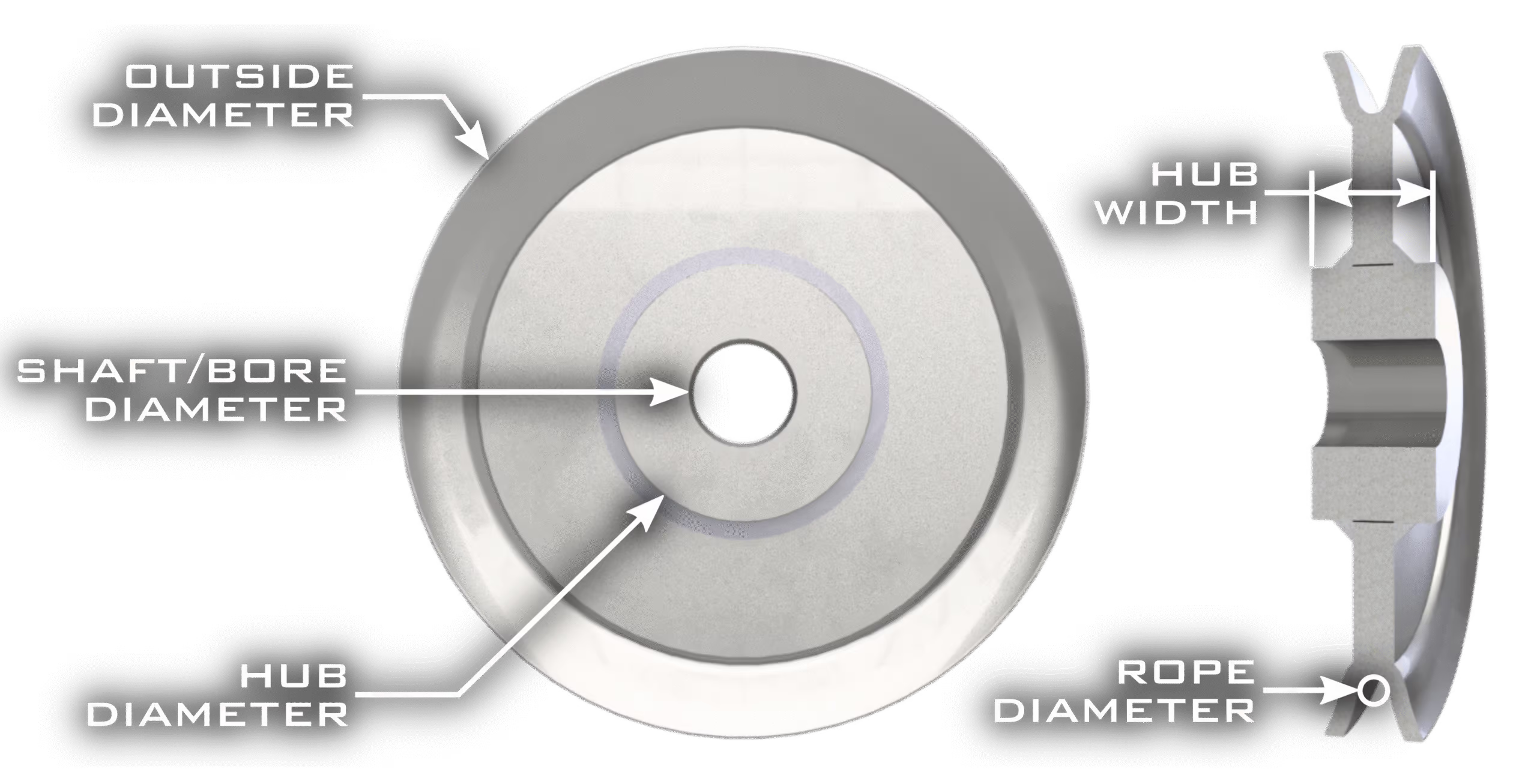

Diagram of a Roll Formed Sheave: