Custom Sheaves

The Bear Equipment Custom Sheave Process:

1. Engineering

Our expert engineering staff quickly understands your needs, provides insights, and translates expectations into production drawings. WE DO NOT CHARGE FOR ENGINEERING! Sheave engineering is what we are good at and what we enjoy doing. If you have an overview of the application with basic information, the Bear Equipment team is ready to assist.

2. Machining

Our state-of-the-art machine and fabrication shop, with experienced machinists and CNC equipment, machines raw materials to precise dimensions. We can machine sheaves from alloy steel, stainless steel, aluminum, nylon, or any other specialty material your application requires.

3. Post-Machining

We offer numerous post-machining processes to ensure the sheave performs optimally in its application. From in-house flame hardening to various coating options such as powder coat or plating, Bear can produce the right sheave for the job.

4. Bore Options

We provide various bore options tailored to your requirements: Plain bore, oilite bushings, in-house machined grooved bushings, keyed bore, and any bearing available. Bear Equipment can provide the appropriate bore option for the application.

5. Quality Control

Quality control is integrated into every step of the Bear Equipment process, from approval drawings to inspecting post-machining processes and ensuring proper installation and functionality of bore options. When you get a Bear Equipment sheave, you know that it’s a quality sheave held to the tightest standards.

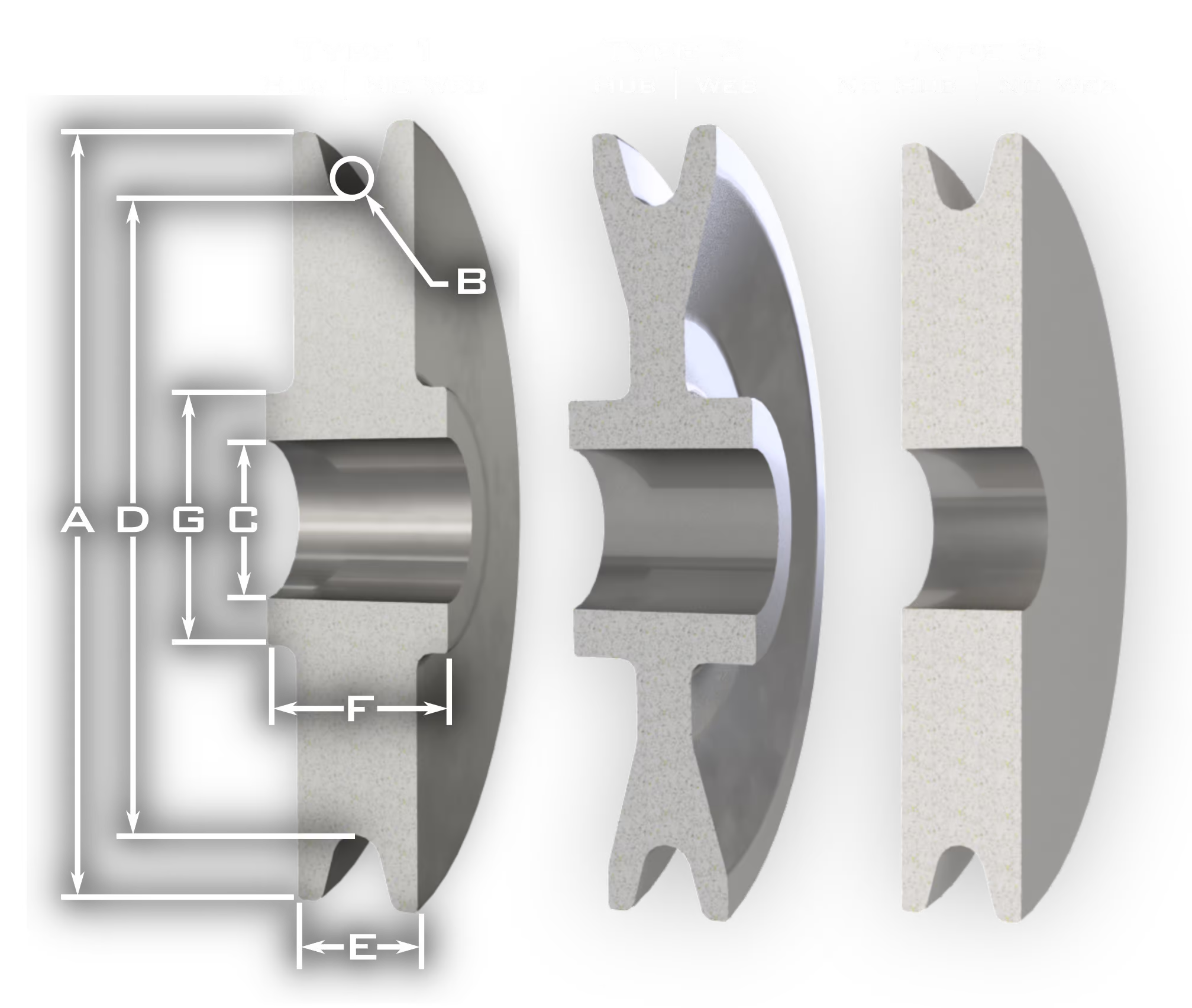

Custom Sheave Quote Form

Please complete the form below to start the process so Bear Equipment can meet and exceed your sheave application needs. Remember BEAR EQUIPMENT DOESN’T CHARGE FOR ENGINEERING so customizing a sheave to your exact needs does not add extra cost.

DOWNLOADS

Click on the link to download the PDF version of the Bear Equipment Custom Sheave Form. The pdf can be filled out digitally or printed to be filled out manually. Please send any manually filled out forms to info@bearequipment.com.

Need Bear to Handle the Measuring?

Send in any sheave that you need replaced or replicated and Bear Equipment can handle the rest. We will inspect and measure every critical dimension, while matching any bore option. Bear can also make suggestions on any improvements to the sheave design that might improve performance in your application.