Custom Manufacturing

With over 100 years of combined experience, Bear Equipment’s Engineering team is a leader in innovative cable routing and winching solutions. Our deep-rooted expertise in engineering for manufacturing allows us to quickly understand your application challenges and translate them into reliable, efficient, and custom-engineered turn-key systems.

Engineering Sales

At Bear, our inside sales department is our engineering team—meaning you’re immediately connected with the most knowledgeable and experienced support. From the first conversation, our engineers work closely with you to define the problem and begin crafting a solution.

Engineering Design

We utilize AutoCAD Mechanical 2D software to produce precise approval and production drawings. For more complex applications, we employ Autodesk Inventor 3D CAD to model solutions and perform finite element analysis (FEA) to evaluate load conditions and ensure structural integrity.

Engineering to Production

Once drawings are customer approved, our engineers collaborate directly with our in-house machine shop to manufacture parts to the tightest tolerances. Bear Equipment is not a “throw it over the fence” engineering to production shop. Our engineers, machinists, and fabricators have worked together for years, combining their areas of expertise throughout the production process to ensure the best end product possible.

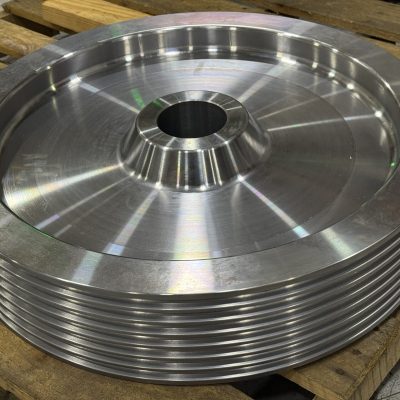

Machining Experience

Bear Equipment machinists have over 80 years of experience in manual and CNC machining, with most of those years specifically in winch and sheave related parts. This deep expertise allows our team to interpret parts beyond their technical drawings—understanding their function and application. As a result, our quality control is inherently robust, with machinists verifying not only dimensional accuracy but also fitment with mating components.

Machining Capabilities

Bear Equipment operates a state-of-the-art machining facility equipped with a range of CNC machining centers, including a CNC horizontal band saw, multiple CNC horizontal lathes (with and without live tooling), a CNC vertical lathe with live tooling, and CNC vertical mills that can be equipped with 5th axis rotary head. Combined with the expertise of our skilled machinists, this advanced equipment enables us to efficiently and precisely machine a wide variety of high-quality parts.

Welding Capabilities

Bear Equipment offers expert welding services backed by certified welders and precision fabrication techniques. Our capabilities include MIG, TIG, and stick welding for a wide range of materials and applications. With a focus on strength, durability, and accuracy, we deliver high-quality welds that meet demanding industry standards.

Process Capabilities

Bear Equipment offers comprehensive post-machining services to enhance part performance and durability. We provide in-house flame hardening and coordinate with trusted local partners for powder coating, painting, and plating. These finishing processes ensure our parts meet both functional and aesthetic standards for a wide range of applications.

Assembly Capabilities

Bear Equipment specializes in the assembly of blocks, fairleads, winches, and other complex mechanical systems. Our team ensures each assembly is built to precise specifications, tested for performance, and ready for your application. With a focus on quality and reliability, we deliver fully assembled solutions tailored to your operational needs.

Custom Blocks

Custom Fairleads

Gears

Track Wheels

Crane Wheels

Winch Drums

Shafts

Pins