Loft Block Bullwheels and Sheaves

Bear Equipment recently completed some bullwheels and sheaves for loft blocks for an opera house. This is an example of how sheaves are used in the theater industry. We provided 9-Groove bullwheels, 7-Groove bullwheels, 16″ diameter sheaves, and 12″ diameter sheaves.

This project highlights the full sheave and bullwheel manufacturing capabilities of Bear Equipment.

Let’s go through the steps to manufacture the bullwheels:

- Sheave Blank: Bullwheel starts with a section of alloy steel roundbar.

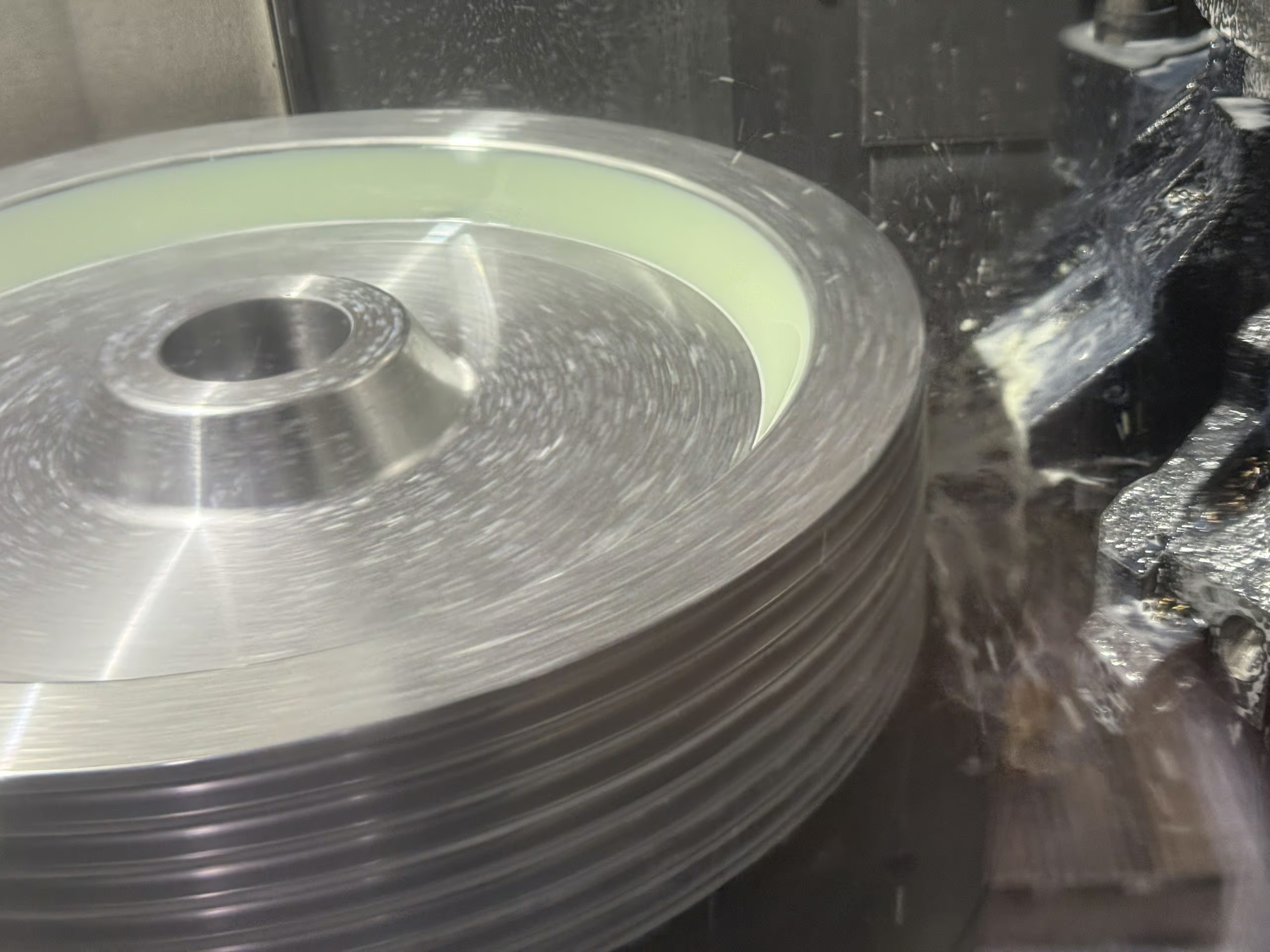

- Pre-Machining Profile: Sheave blank is placed in our CNC vertical lathe. The outer profile and inner bore is machined.

- Machining Grooves: Rope groove profiles are precision machined.

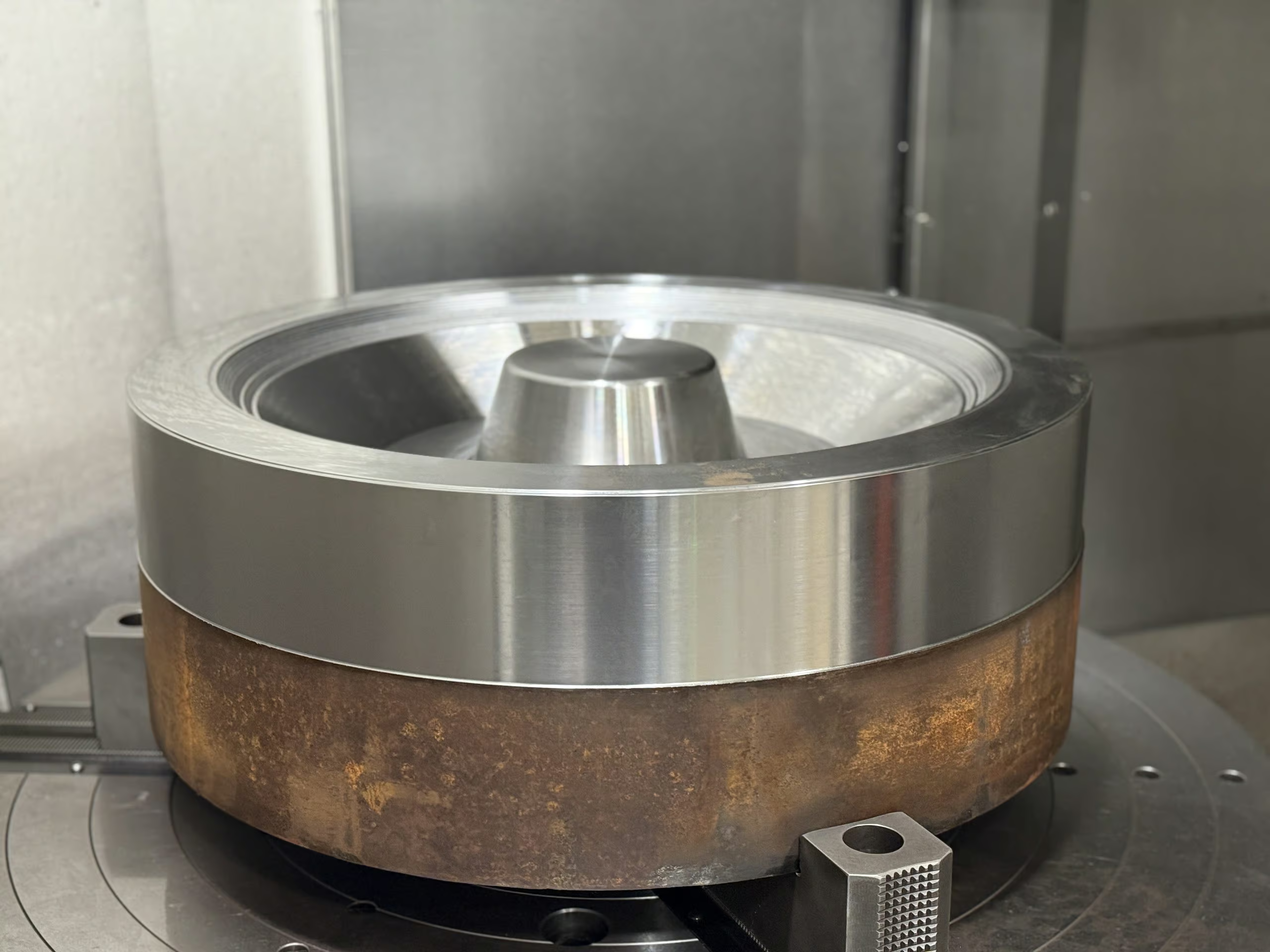

- Machining Lightening Holes: Bullwheel placed in our CNC vertical mill and four lightening holes machined to reduce overall weight.

- Bore Keyed: Keyway is broached into the bore to match the customer’s shaft specifications.

- Flame Hardening Grooves: Each groove is flame hardened and tested to a specified minimum hardness to improve groove life.

- Powder Coating: Bullwheel is powder coated to increase corrosion resistance and improve aesthetics.

The custom projects is what Bear Equipment excels at. Contact us today to solve your sheave or bullwheel needs.

Picture of the sheave blank:

Picture of the outer profile of the sheave being machined in our CNC vertical lathe:

Picture of the grooves being machined in our CNC vertical lathe:

Picture of the lightening holes being machined in our CNC vertical mill:

Picture (up close) of the keyway after it had been broached:

Picture of the grooves being flame hardened and a Bear Equipment engineer testing the hardness:

Picture of the bullwheel after it had been powder coated: