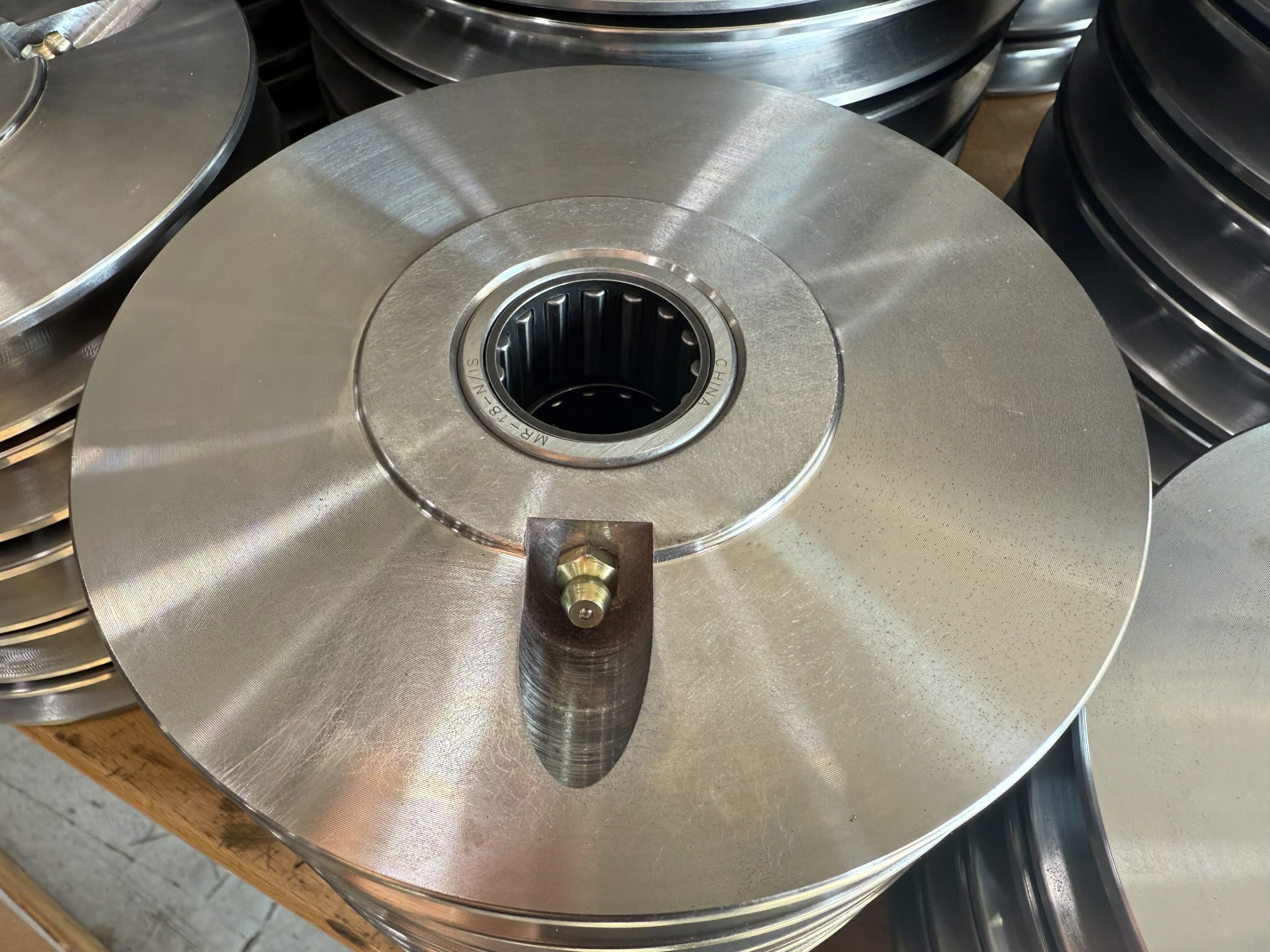

Sheave with Greaseable Hub

Bear Equipment can machine sheaves with greaseable hubs to allow easy lubrication of the sheave bearing via a grease fitting.

Below is a closer picture of the greasebale hub in sheaves used for a mobile hoist application:

How do greaseable hubs work?

First thing to understand is the bearing itself. In this application, a needle bearing is being used. There is a grease groove machined into the outer diameter of the bearing with ports that allow the grease to enter the inner race of the bearing.

See the picture below of a needle bearing and note the grease groove and port:

For grease to access this groove when the bearing is installed into the sheave bore, a pathway must be machined that directs grease to the grease groove on the bearing. The picture below is a cross section view of a greasable hub:

To machine a greaseable hub, the sheaves are first machined in our CNC lathes to the precise outer dimensions and groove profile. Next, the sheaves are placed in our CNC vertical mill. The sheave is set at the appropriate angle that when the grease pathway is machined, it will line up with the grease groove on the bearing. The larger diameter face is machined first, then the grease pathway hole is drilled. The grease hole is then tapped to allow installation of a threaded grease fitting.