Custom Snatch Block Sheaves

Bear Equipment is your custom snatch block sheave manufacturer.

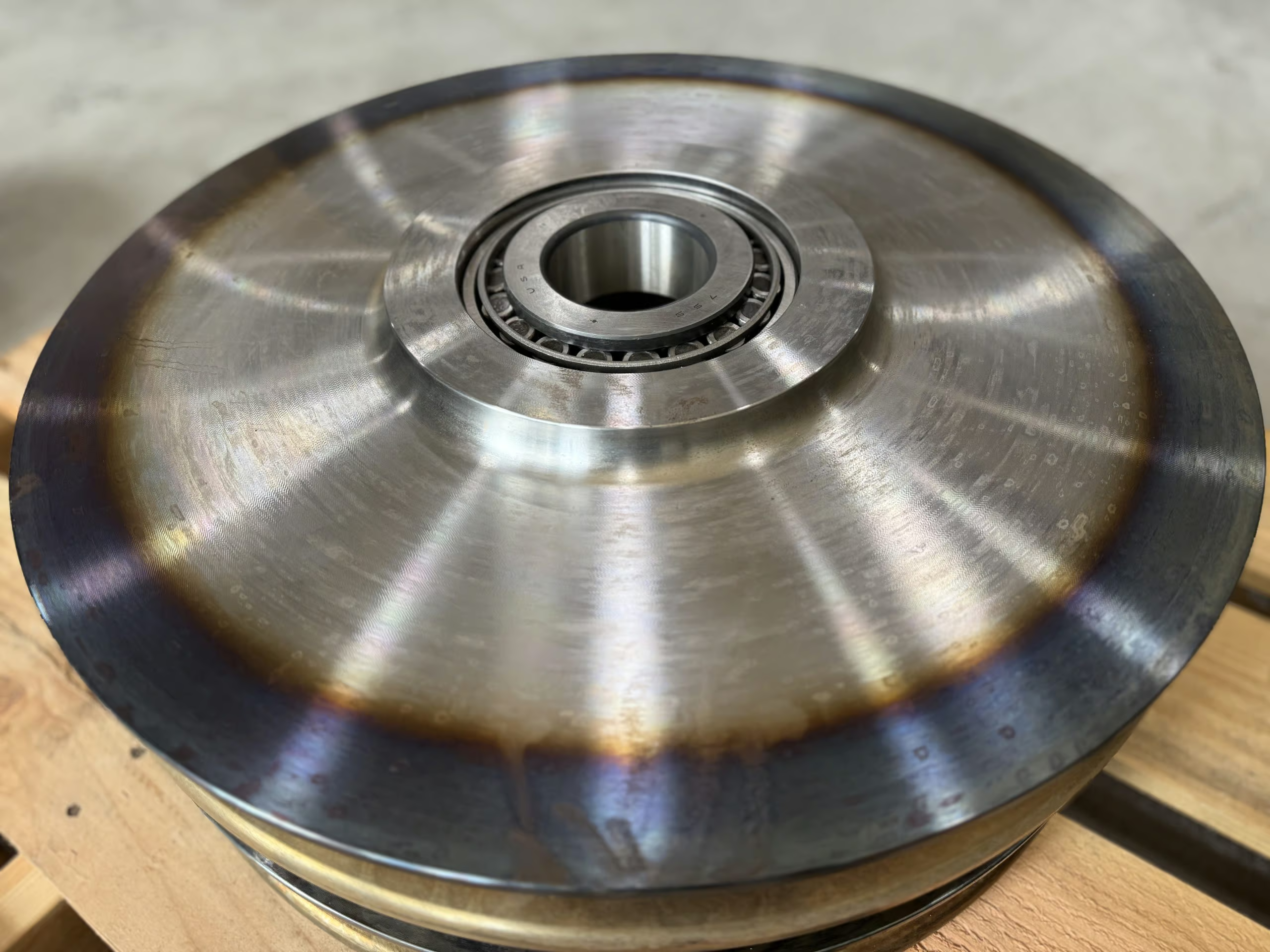

Here is a recent example: 22″ outer diamater | 3″ diamater shaft | Grooved for 25mm wire rope | Flame Hardened Groove

This sheave has two key features that make it ideal for snatch block applications:

- Flame Hardened Groove: The groove is hardened to prolong groove life to minimize snatch block maintenance.

- Tapered Roller Bearings: High-load roller bearing in both the radial and axial direction.

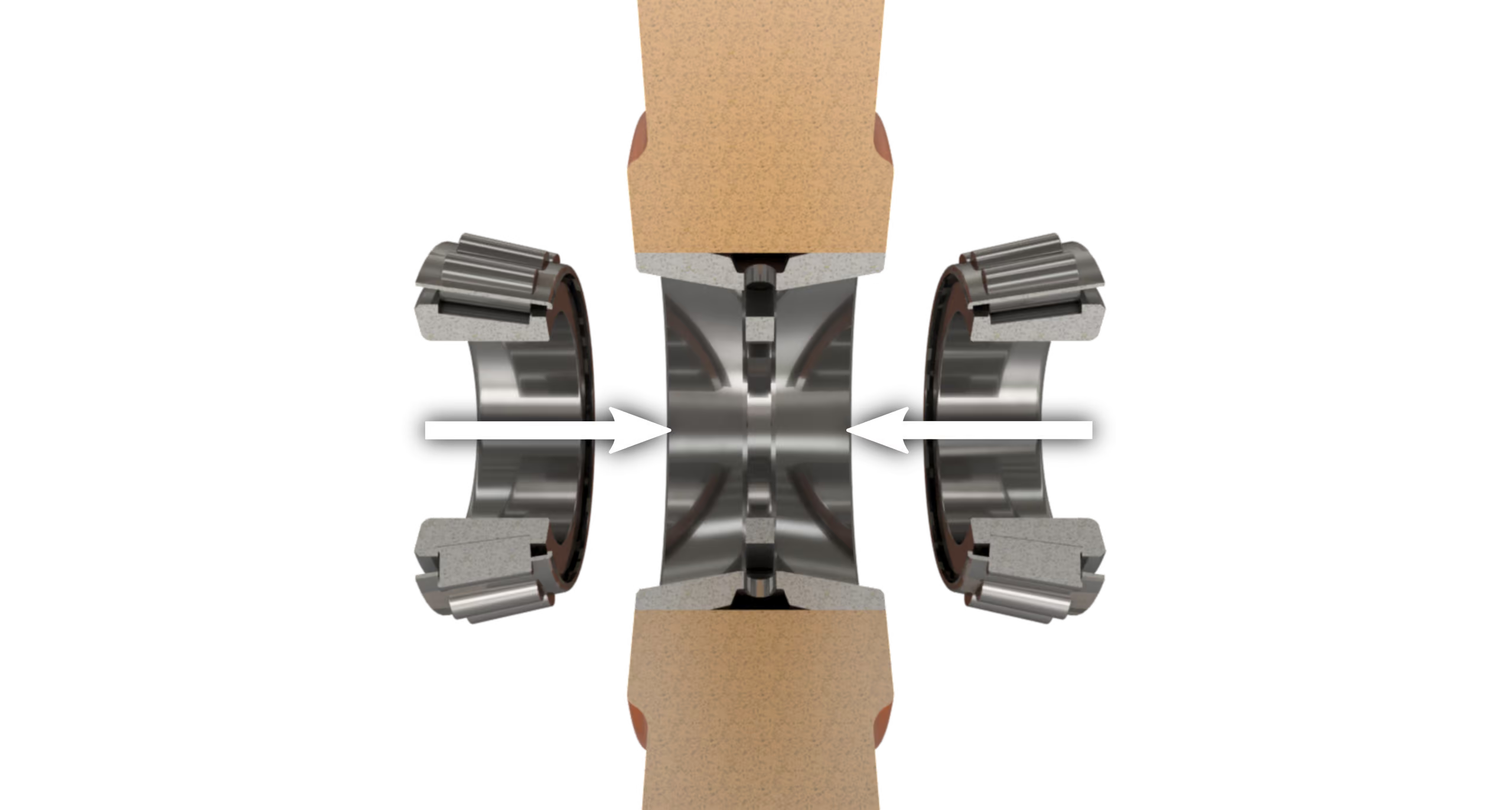

Tapered Roller bearings are used in high-load situations and feature a cup/cone setup. The cup is the outer race of the bearing and the cone if the inner race. The cone is comprised of cylindrical rollers arranged in a cone shape that fits into the tapered cup.

Below is a picture of the sheave with the cone removed:

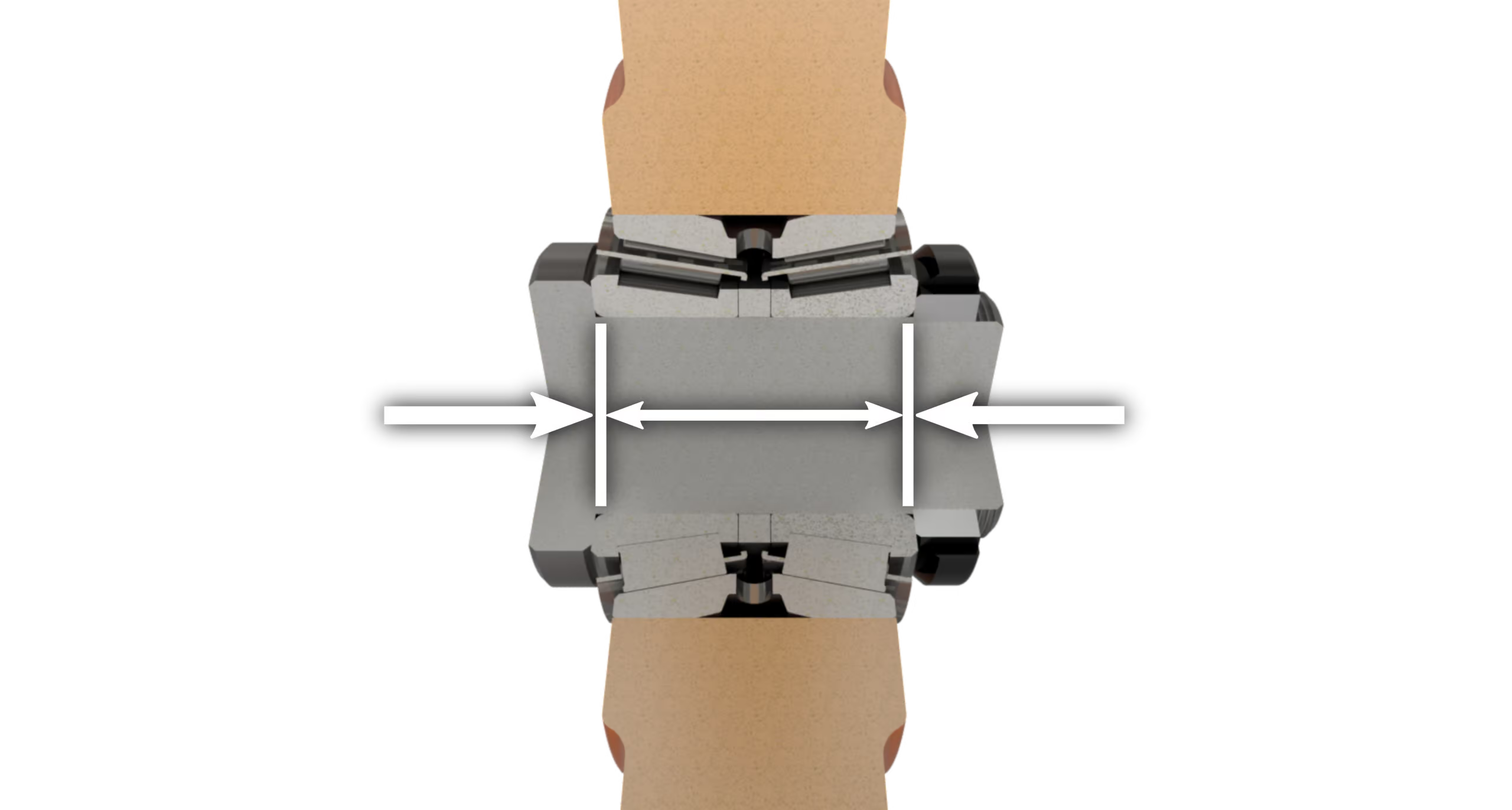

Since the cones can be removed from the cup, some design considerations must be taken. First, tapered roller bearings must be used in pairs to handle forces in both axial directions. Second, the cones must be captured aixially.

Below shows a section view of a tapered roller bearing in a sheave with the cones disassembled from the cup:

The diagram below shows how tapered roller bearings must be captured axially:

There are multiple ways to capture the bearings axially, but the most common is the use of a threaded shaft with a bearing nut. The setup is key in allowing a snatch block to be opened at the top, in order to insert the rope, while keeping the sheave/bearings/shaft captured.

Contact Bear Equipment today if you have any snatch block sheave needs.