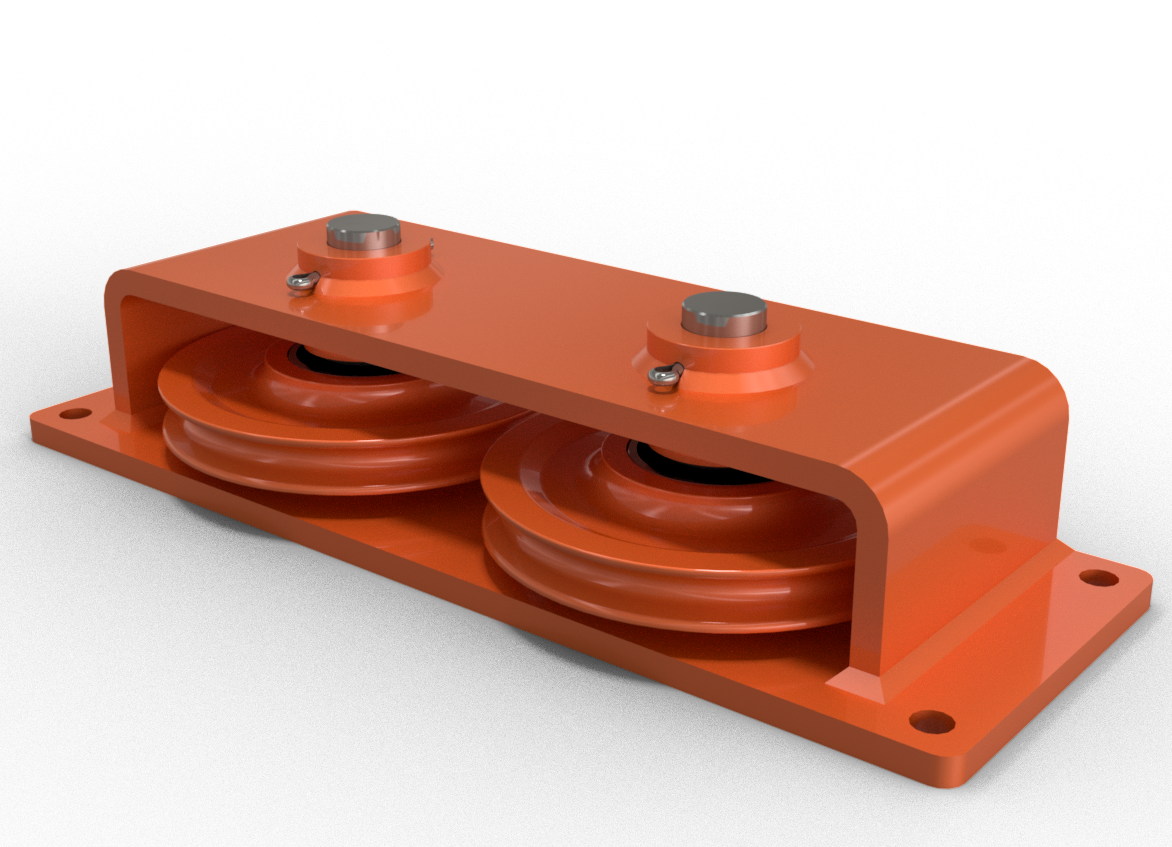

Double Horizontal Blocks

About Double Horizontal Blocks

Jeamar double horizontal blocks are heavy-duty block designed for the most demanding applications. Utilizing Jeamar two standard sheaves and welded frame, these blocks come in powder coated stee. The dual sheaves allow for a wide range of cable paths, ideal for a dynamic cable routing application. Jeamar blocks have been trusted for 50 years to be a reliable cable routing solution.

Specifications

Duty:

Heavy Duty

Material:

Steel, Stainless Steel

Outer Diameters:

2-1/4" - 26-3/8"

Allowable Rope:

1/8" - 1-3/8"

Bore Options:

- Ball Bearings

- Cylindrical Bearings

- (Large size sheaves)

Flame Hardening:

- Available Upon Request

- (Not Standard)

Coating:

- Powdercoat (Steel)

Advantages of Double Horizontal Blocks

High Strength to Weight Design

Alloy steel sheave with machined web profile reduces unnecessary weight and provides highest strength to weight ratio.

High Sheave-to-Rope Ratio

Minimum 16:1 sheave outside diameter to rope diameter ratio to reduce rope bending stress and increase rope life.

High Working Load

Double Horizontal Blocks allow full 180 degree of horizontal rope exit to ensure proper cable routing to maximize rope life.

High Efficiency Bearing

Sheaves utilize either ball bearings or cylindrical roller bearings for reduced friction, smooth motion, and lifetime lubrication.

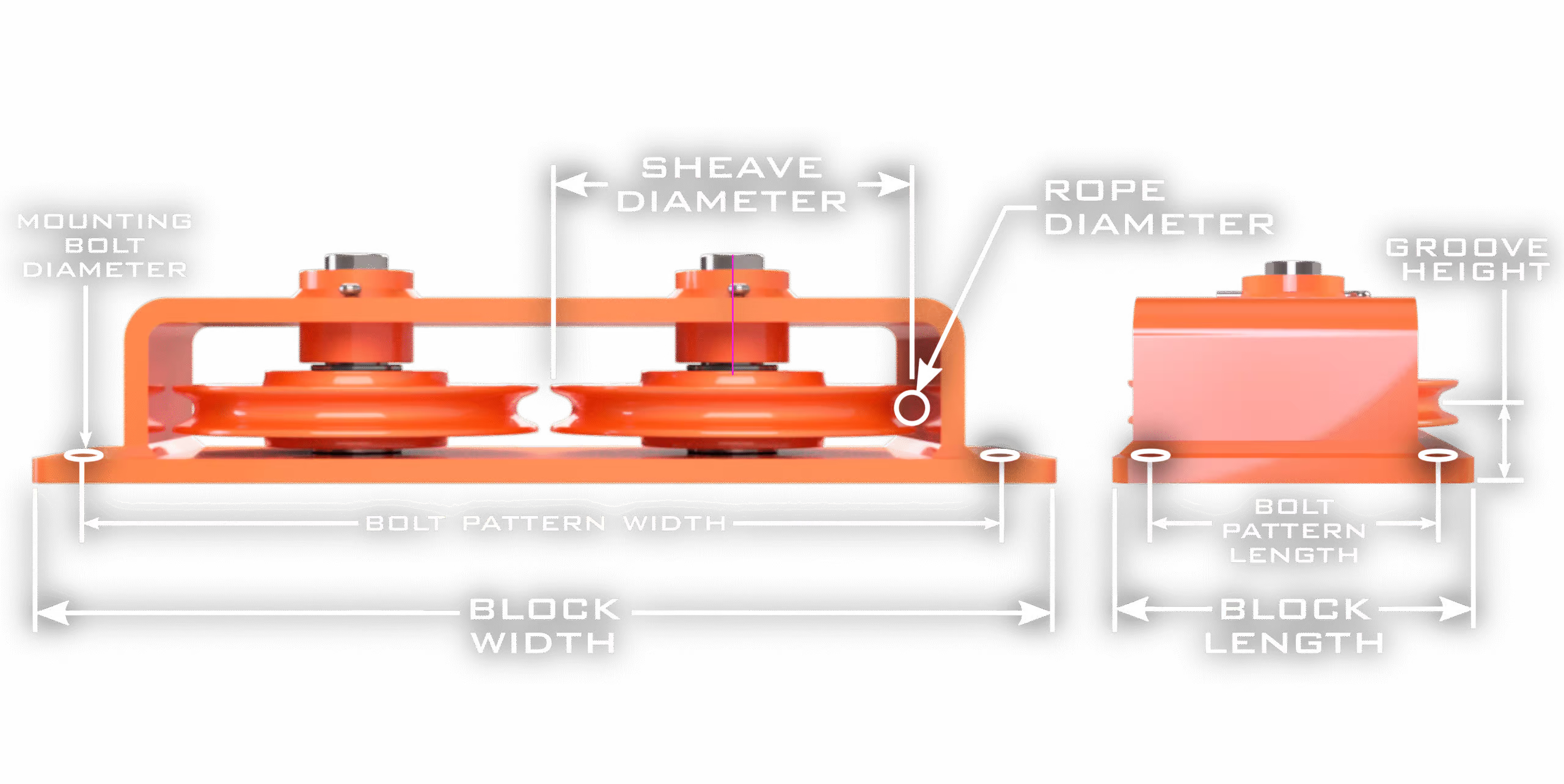

Diagram of a Double Horizontal Block

Product Table

Simply add any item to your cart and complete the Request for Quote (RFQ) form. A member of our sales engineering team will respond promptly with pricing and availability.

Scroll Sideways on Your Mobile Device to View Product Data and the RFQ Button.

Product Tables Are Easier To See on Desktop Computers.

Model | WLL (LBS) | Sheave Diameter (IN) | Rope Diameter (IN) | Overall Length (IN) | Overall Width (IN) | Groove Height (IN) | Bolt Patt Length (IN) | Bolt Patt Width (IN) | MT Bolt Diameter (IN) | RFQ CART |

|---|---|---|---|---|---|---|---|---|---|---|

FA3500 | 3500 | 4.25 | 1/4 | 11.625 | 4 | 1 | 10.75 | 3 | 3/8 | |

FA7000 | 7000 | 6 | 3/8 | 16 | 5.5 | 1.25 | 15 | 4.5 | 1/2 | |

FA10500 | 10500 | 8 | 1/2 | 21 | 7.25 | 1.5 | 19.5 | 5.75 | 5/8 | |

FA16000 | 16000 | 10 | 5/8 | 26.625 | 9 | 1.75 | 24.63 | 7 | 3/4 | |

FA23000 | 23000 | 12 | 3/4 | 32.5 | 11 | 2 | 30 | 8.5 | 1 | |

FA31000 | 31000 | 14 | 7/8 | 37.625 | 12.5 | 2.38 | 34.63 | 9.5 | 1-1/4 | |

FA41000 | 41000 | 16 | 1 | 43.125 | 14.5 | 2.63 | 40 | 12 | 1-1/2 | |

FA52000 | 52000 | 21.54 | 1 1/8 | 55.25 | 21.5 | 2.56 | 51.38 | 17.5 | 1-1/2 | |

FA68000 | 68000 | 23.54 | 1 1/4 | 60.375 | 23.5 | 2.75 | 56 | 19.25 | 1-5/8 | |

FA83000 | 83000 | 26.34 | 1 3/8 | 67.5 | 26.375 | 3.13 | 62.63 | 21.5 | 1-7/8 |

Disclaimer: Due to our policy of continuing development, all specifications are subject to change without notice. Users of these products are responsible for ensuring their suitability for the application in which they are being used.